Our competence primarily involves the numerical modeling of flow conditions occurring in fluid dynamic equipment and special spaces, as well as the numerical investigation of heat exchange processes taking place in heat-technical equipment using fluid mechanics approaches (CFD).

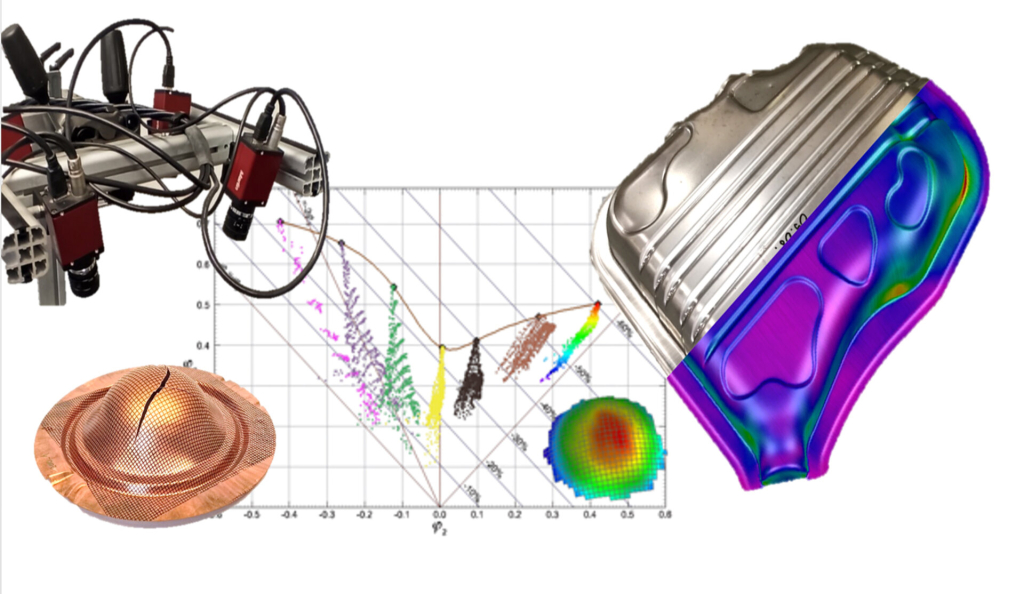

Empowering metal forming in the automotive industry through cutting-edge technology planning. Services include virtual investigations and hands-on training. Trusted by industry leaders.

Elevate your products with our NVH expertise. Precise measurements, comprehensive knowledge. Services include noise reduction solutions. Tools: B&K data acquisition, laser vibrometer.

Revolutionize manufacturing with our expertise in additive technologies. From materials to 3D printing, we lead innovation for aerospace, automotive, and toolmaking.

With the competence of researchers at the University of Miskolc and its world-class infrastructure, we assist particularly those involved in vehicle, machinery, and automotive manufacturing, as well as the metal processing sector, in the investigation and resolution of manufacturing issues, customer complaints, and incidents. Our expertise extends to solving any problems related to the material structure of components or products, both at the raw material level and during operation.

In addition to the production and examination of nanostructures, our main focus is on the investigation of interfacial phenomena. We primarily determine the wetting degree using the static drop method, which is particularly crucial in soldering and in the production of water-repellent, self-cleaning coatings. In the synthesis of nanomaterials, we specialize in the production and analysis of bulk and surface nanocomposites, phase-change materials, thin films, multilayered structures, metal and ceramic nanoparticles, and carbon nanostructures.

Logistic planning, development, and testing in the field of packaging and unit load formation. Optimized tools and services tailored to the increasing demands of freight transport.

The focus is on the improvement of various companies' logistic processes using Lean tools. This area is of paramount importance as the reduction of losses through the Lean philosophy can significantly enhance the competitiveness of companies.

At the core of the competency area is the optimization of production and service logistics processes, encompassing the integrated management of installation, route planning, loading, storage, and scheduling issues.

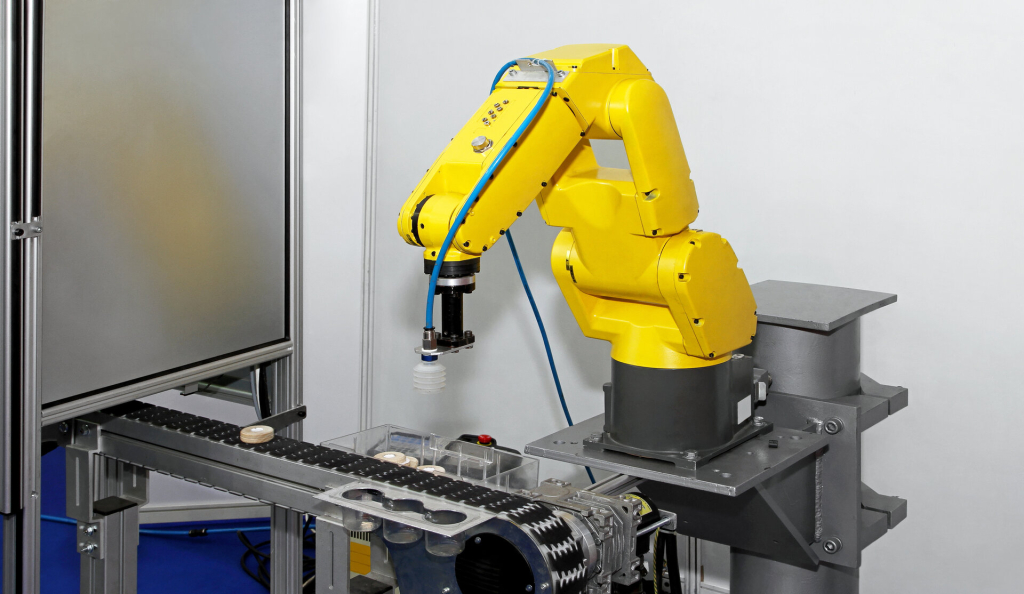

This focus area primarily aims to provide the installation, programming, and development of case studies for industrial robots. In line with the requirements of the present era, industrial robots are integrated into logistics processes, thereby enhancing productivity. Furthermore, such systems are suitable for addressing the current labor shortages.

The competence in robotics and PLC programming at the Institute of Machine Tools and Mechatronics primarily focuses on the installation and programming of industrial robots, creating case studies, and programming PLCs. In line with the requirements of the present era, industrial robots and PLCs are integrated into various manufacturing processes to enhance productivity...

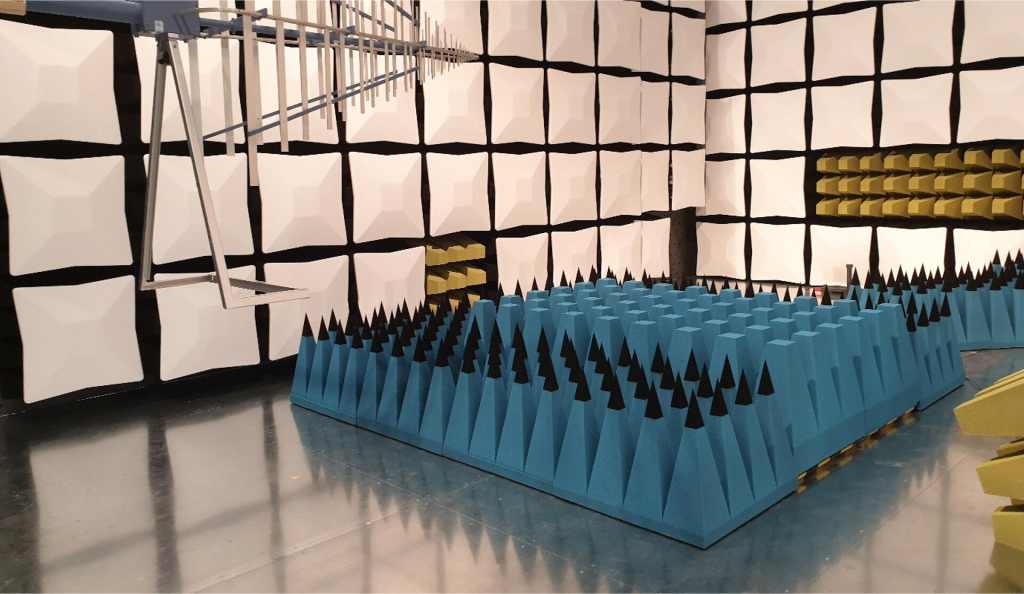

At the University of Miskolc, a new EMC (Electromagnetic Compatibility) laboratory was established in 2020 to meet industrial needs. The laboratory is equipped for measuring radiated and conducted interferences of automotive and commercial electronic devices, as well as conducting standardized Electrostatic Discharge (ESD) tests.