Polymer technology services encompass the design of polymer systems, starting from compounding and processing technologies to additive systems.

Specializing in casting technology, our lab provides accredited training and comprehensive services for automotive and various industries, addressing all foundry requirements.

The qualitative and quantitative characterization of chemical systems is primarily achieved using spectroscopic techniques. If the spectroscopic properties of chemical particles cannot be measured for technical reasons, their spectral characteristics can be calculated. Due to the robustness of quantum chemical calculations, the computed spectrum is suitable for structural identification and prediction of the spectral properties of molecules.

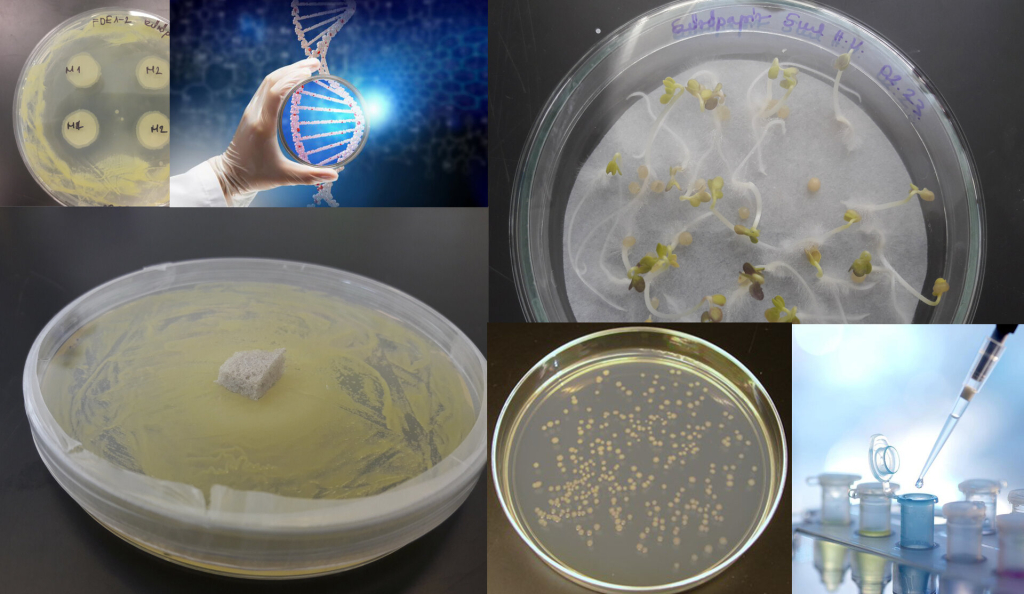

Examination of toxicity of modern materials, antibacterial effects, and molecular biological analysis of magnetic nanoparticles. Key focus areas: Modern materials, toxicity, antibacterial effects, magnetic nanoparticles, molecular biology.

Experience unparalleled precision and reliability in material testing with our advanced laboratory services. Our comprehensive capabilities cover mechanical and physical properties, backed by cutting-edge instrumentation and expertise. Partner with us for thorough evaluation and precise analysis, ensuring top-notch quality and performance for your materials.

Researching, developing, and applying hot and cold forming technologies for the production of semi-finished products. They play a crucial role in regulating material properties, aided by computer modeling and mechanical testing to assist in design.

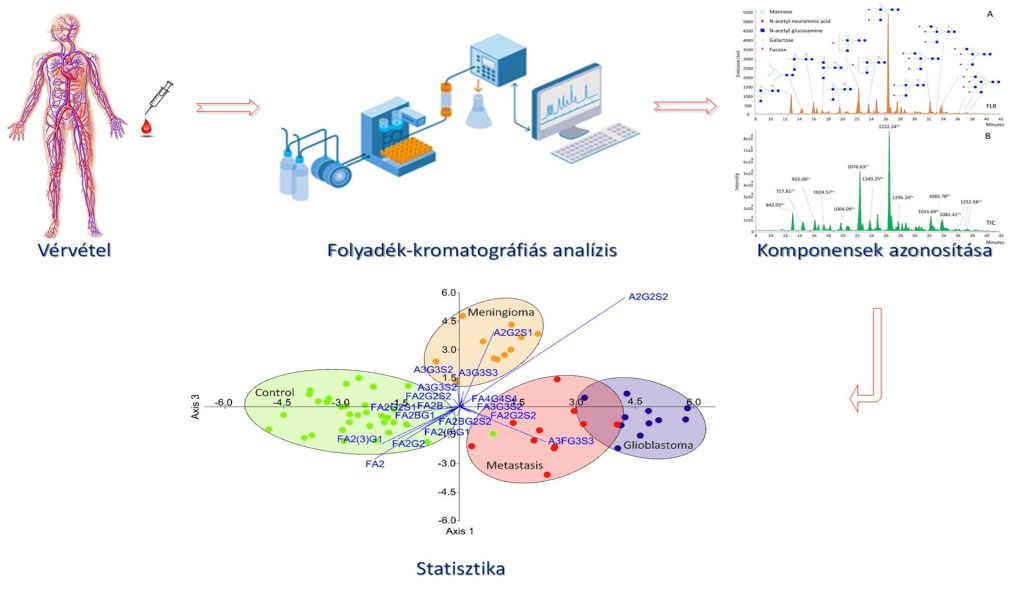

We specialize in molecular analysis of biological samples, particularly focusing on post-translational modifications such as glycosylation. Additionally, we excel in quality control of monoclonal antibodies, including intact protein analysis and identification of various aggregates, along with the identification of post-translational modifications of proteins.

We specialize in advancing ceramics and silicate industries through testing, research, and optimization of materials and manufacturing technologies, including exploring secondary raw materials for sustainability.

In our research, development, and applications related to hot and cold forming, we primarily focus on technologies associated with the production of semi-finished products. In both process groups, controlled alteration of material properties (mechanical and/or thermo-mechanical) plays a crucial role alongside shaping.

Specializing in renewable energy technology development and sustainability solutions, we analyze, develop, and implement innovative approaches to optimize energy production and reduce carbon emissions.

One of the crucial separation operations in the chemical industry is distillation and extraction. The efficiency of distillation depends on how much the composition of the liquid mixture differs from the composition of the vapor in equilibrium with it. The design of distillation processes can only be done with knowledge of the vapor-liquid equilibrium.

Our main area of expertise lies in the development, optimization, and evaluation of hydrometallurgical and pyrometallurgical processes. We particularly focus on pyro- and hydrometallurgical methods suitable for processing and neutralizing metal-containing solid and liquid waste materials.

- 1

- 2