Patent - PATENT APPLICATION

Protective form: Patent protection

Case number:

P1900380

Filing date:

2019.11.11

Title of the invention:

Enhanced Antibacterial Polyurethane Foam and Method for its Production

Description:

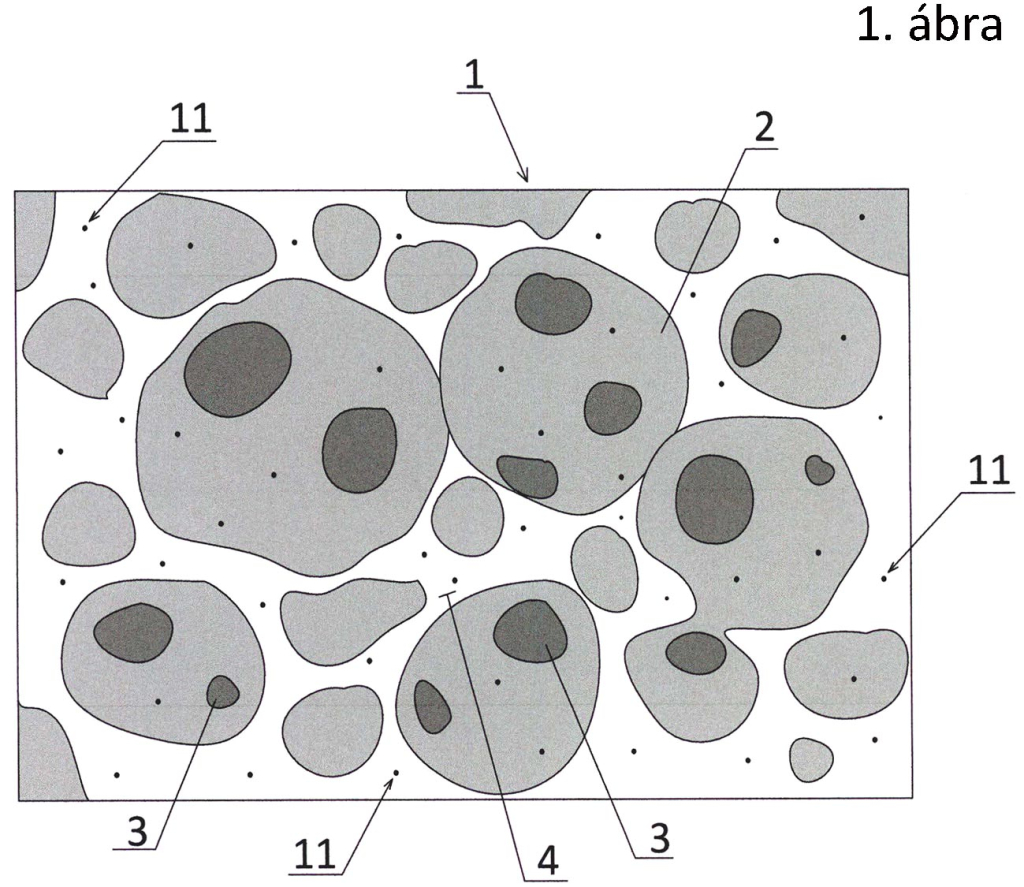

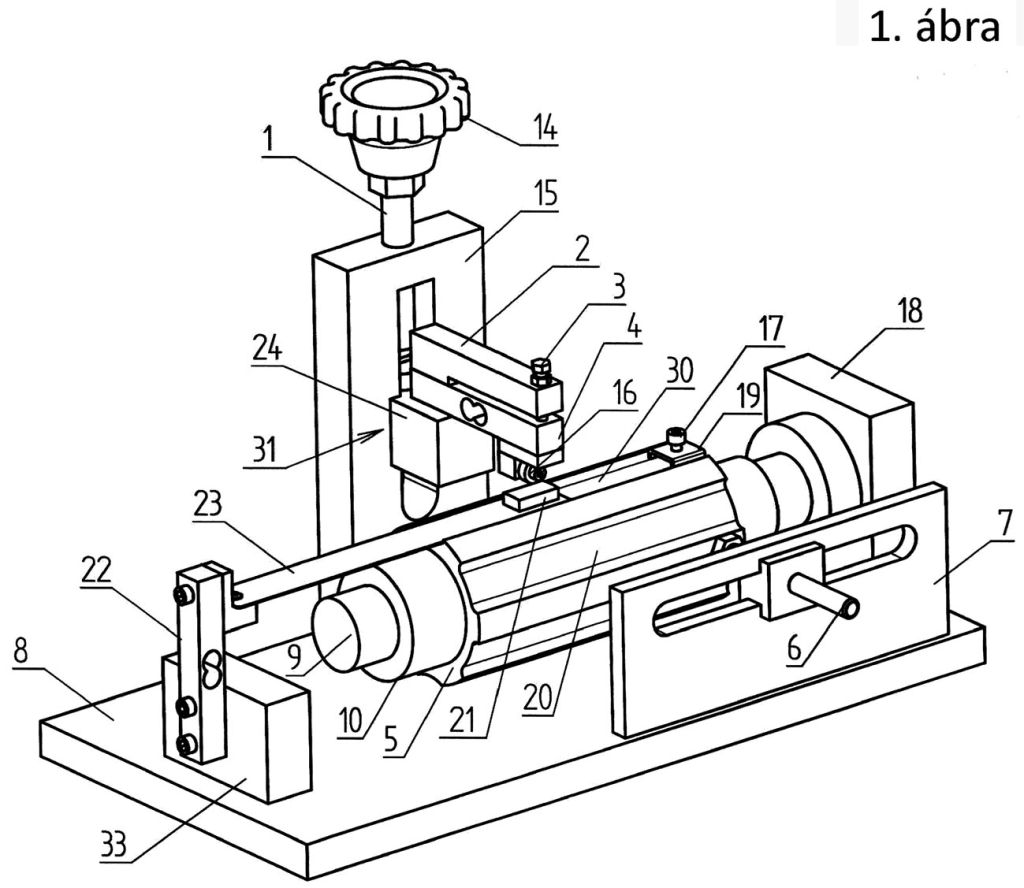

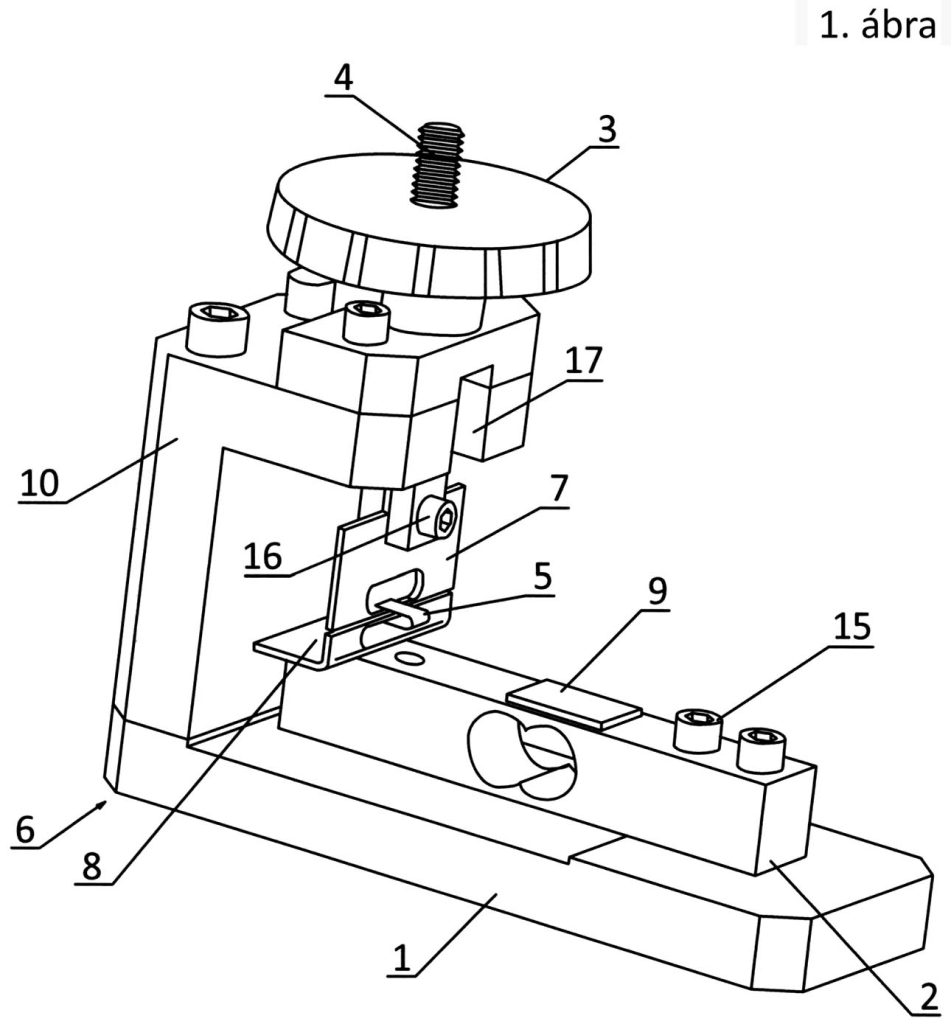

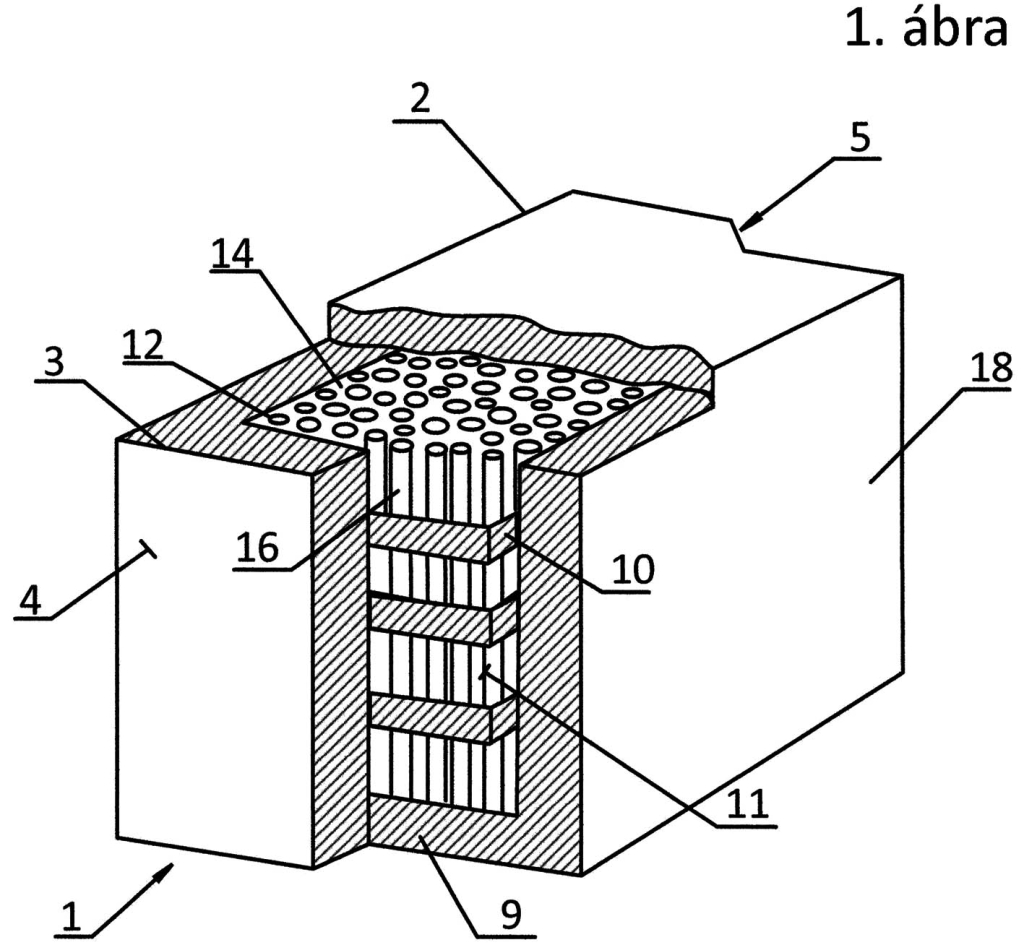

The subject of the patent is an enhanced antibacterial polyurethane foam, consisting of urethane bonds formed from the reaction of isocyanate and polyol, with a cellular structure of open or closed cells and an antibacterial additive containing silver in the matrix forming the cell walls of the foam structure. The antibacterial polyurethane foam (1) contains an antibacterial additive (11) of nanosilver droplets (16) with a size between two nanometers and one hundred nanometers on the surface of mineral rhyolite tuff (15), which are present in a non-charged, metallic state on the surface of the rhyolite tuff powder (20). The mineral rhyolite tuff (15) contains at least 40 weight percent smectite (8), with a minimum of 30 weight percent of the smectite being montmorillonite (9) clay mineral. The smallest particle size of the rhyolite tuff powder (20) is 300 nanometers, and the largest particle size is 1300 nanometers. Furthermore, the subject of the patent is a method for producing enhanced antibacterial open or closed-cell polyurethane soft foam, by performing the chemical reaction of isocyanate and polyol in a closed or open mold cavity, with foaming to shape (85). The production of the antibacterial additive (11) uses an antibacterial additive production process (83), in which the mineral rhyolite tuff (15) is pretreated with grinding (53) in equivalent alcohol (84), followed by vacuum evaporation to remove the liquid grinding medium (54). Reacting (56) ethanol (71) and silver nitrate (72) are added to the rhyolite, followed by homogenization (57) after the reaction (56), then vacuum separation (58) of acetaldehyde (74) and nitric acid (75) is performed, and the dry silver-containing rhyolite substance is suspended in the polyol component (62). The resulting suspension is used directly before polyurethane foam development to produce a polyol reaction mixture, to which isocyanate is added for foam formation (63) (77) to foam the mixture into shape (85) for later use (82).

Inventors: Dr. György Czél, Dr. László Vanyorek, Dr. Emma Szõri-Dorogházi