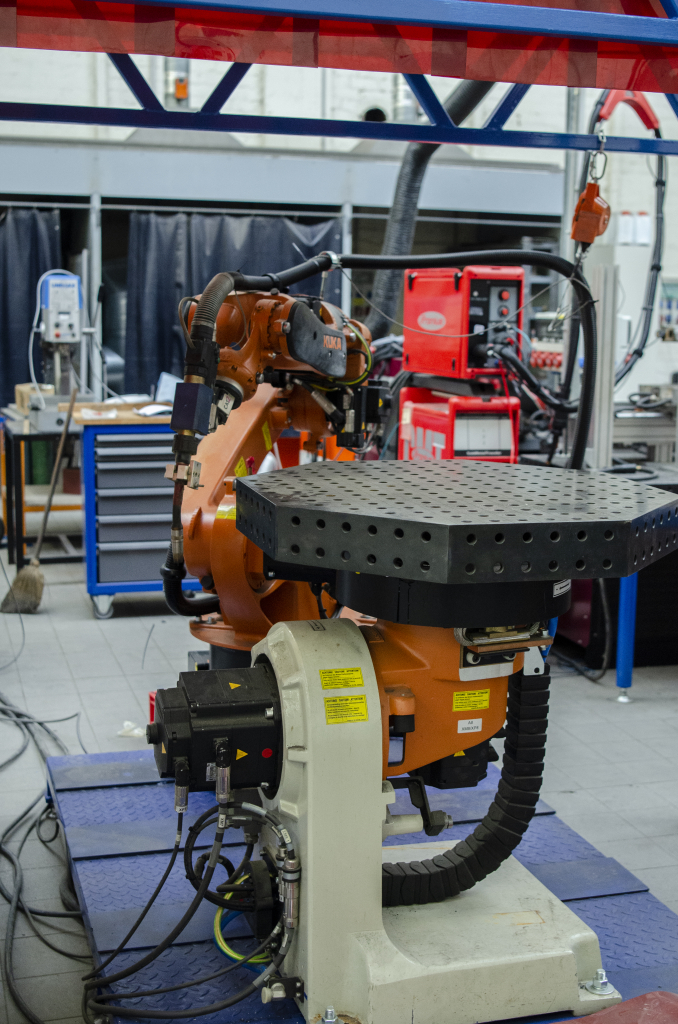

During the “Experimental Design and Optimization of Robotic Wire Arc Welding with Gas Shielded Arc Welding Technology” operation, the following equipment is utilized:

Robot: KUKA KR16 arc HW robot with workpiece rotator Welding equipment: Fronius CMT Advanced 4000 The specifications are as follows:

- Maximum current: 400 A

- DC (direct current) technology

- Pulse technology

- CMT (Cold Metal Transfer) technology, a low heat input welding method

In the “Experimental Design and Optimization of Robotic Wire Arc Welding with Gas Shielded Arc Welding Technology,” the KUKA KR16 arc HW robot with a workpiece rotator and the Fronius CMT Advanced 4000 welding equipment are employed. These devices enable welding processes with a maximum current of 400 A, direct current (DC) technology, pulse control, and the application of Cold Metal Transfer (CMT) technology. CMT technology is a low heat input welding method, particularly suitable for delicate materials.

With the help of these devices, we conduct experimental design and optimization of robotic wire arc welding with gas-shielded arc welding technology, ensuring the quality and efficiency of the welded structures.

Photo: