This competency focuses on surface topographic and geometric measurements for quality control purposes in industrial and custom parts manufacturing. It involves examining the surface roughness, form accuracy, and three-dimensional coordinates of parts using various measurement techniques and tools.

COMPETENCIES:

- Two- and three-dimensional surface roughness measurement and analysis

- Examination of form accuracy of parts

- Three-dimensional coordinate measurement

- Measurements using profile projector and conventional devices

- Examinations using a stereomicroscope

SERVICES:

- Surface roughness measurement and analysis with mobile and fixed roughness measuring devices

- Measurement and analysis of shape and position errors

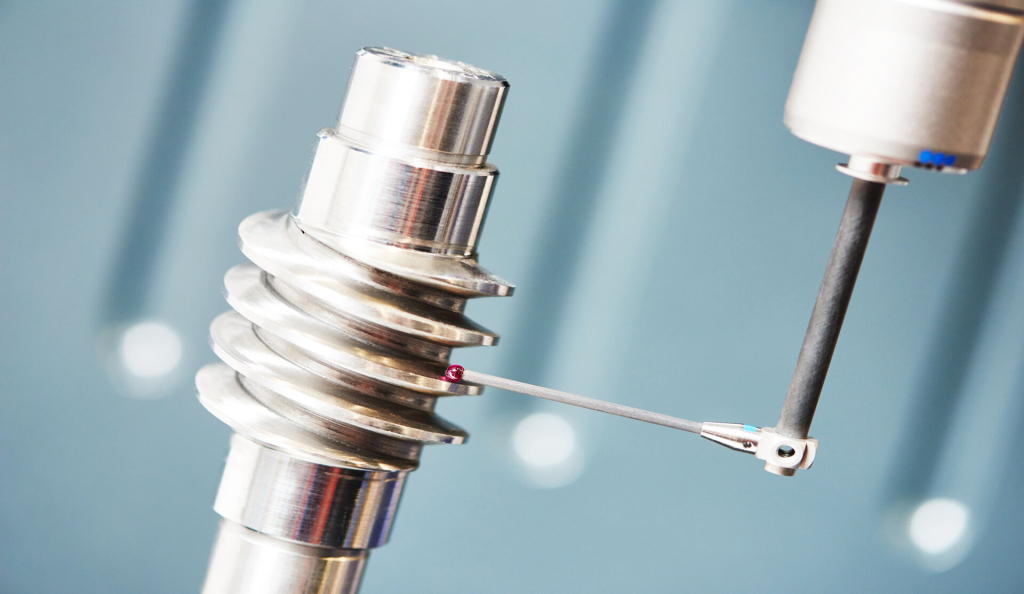

- Three-dimensional geometric measurements with CNC coordinate measuring machines

- Geometric measurements with conventional tools and profile projectors

- Stereomicroscopic imaging and analysis

TOOLS:

- AltiSurf 520 3D measuring device for surface topography with AltiMap evaluation software

- Talyrond 365 shape and position tester with Ultra evaluation software

- Mitutoyo SJ-310 portable roughness tester

- Zeiss Stereo Discovery V.8 stereomicroscope with AxioVision evaluation software

- Mitutoyo PJ-A3000 profile projector and digital measuring instruments

- Dea Global Classic 050505 3D coordinate measuring machine

REFERENCES:

- VT Plastic Manufacturing Ltd.: Surface roughness measurement on plastic prism parts

- BorsodChem cPlc.: Surface roughness measurement of UK-2870 hydrochloric acid compressor components

- Robert Bosch Energy and Body Systems Ltd.: Measuring the depth of scratches on aluminium cover parts

- Bay Zoltán Applied Research Nonprofit Ltd.: Optical profilometric tests on anodized aluminium alloy samples