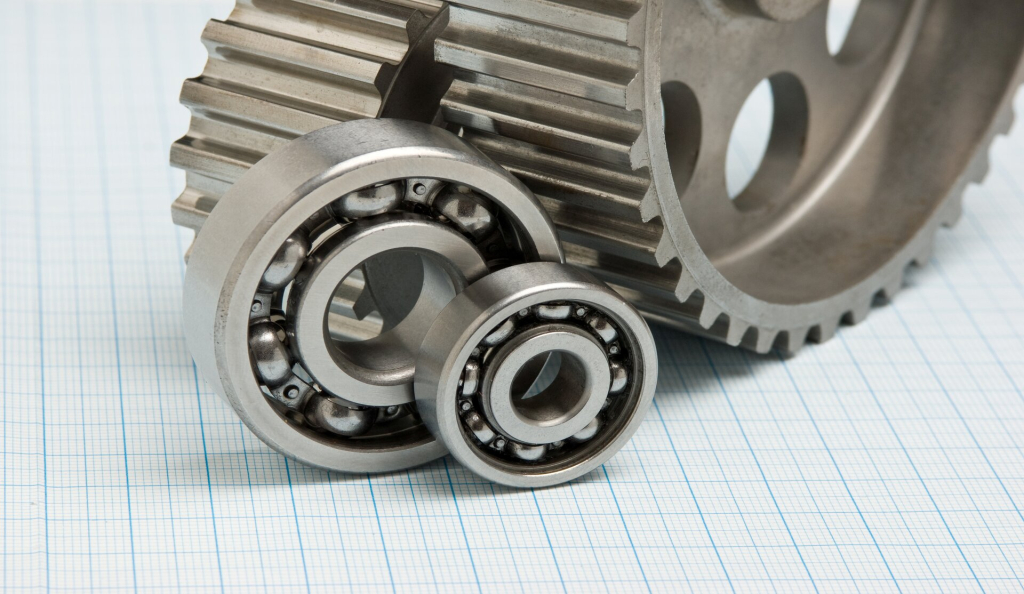

Our expertise lies in the thorough understanding and analysis of bearing and sealing tasks for rotating and oscillating machine parts across various industries. We specialize in selecting suitable elements for installation environments, investigating failure causes, and optimizing lubrication systems for environmental sustainability.

Competencies:

- Control calculation, testing, and design of plain bearings

- Conversion of plain bearings to environmentally friendly lubricants

- Evaluation of shaft deformation’s impact on bearing and sealing systems

- Design and failure analysis of rolling bearings

- Expertise in contact and non-contact dynamic sealing tasks

- Selection and design of suitable seals and connecting machine elements

Services:

- Root cause analysis and solution finding for bearing errors and sealing issues

- Fault detection and troubleshooting for bearing and sealing systems

- Design and redesign of plain and rolling bearings

- Proposal development for environmentally friendly lubrication solutions

Tools:

- Ansys finite element software system (industrial version) for advanced simulations

- Self-developed program for testing axles with statically indeterminate support

- Inspection capabilities for specific industrial components such as clinker kiln bearings, conveyor reversing rollers, Kaplan turbine main bearings, and tubular turbine shafts

References:

- Successful resolution of bearing and sealing faults in various industrial contexts

- Design and implementation of innovative solutions to prevent recurrence of failures

- Collaboration with organizations like HCM and Tiszavíz Vízerőmű to optimize bearing and sealing systems for enhanced performance and safety

Partner with us for comprehensive solutions to your bearing and sealing challenges. We are committed to delivering reliable and environmentally sustainable outcomes tailored to your specific needs.