Additive technologies are playing an increasingly important role in shaping today’s industry. The technology requires a newdesign approach: a drastic rethink of design methods, a radical transformation of the design process. The possibilities offeredby the generative design process can be used to create ultra-light, sufficiently rigid structures for, for example, aerospace,automotive and toolmaking use. The centre follows the processes of raw material production – product design – prototype or series production control – quality checking, including the training of specialists.

COMPETENCIES:

- Production and development of additive production materials and metal powders

- Development of parts and products in terms of AM (Additive Manufacturing), optimization in terms of topology and printing

- Software conversion between designed parts and digital prototype products for additive production

- Printing of designed parts and products

- Post-manufacturing

- Examination of manufactured parts and products (material testing, structural testing, residual stress, anisotropy, CT, functional tests)

SERVICES:

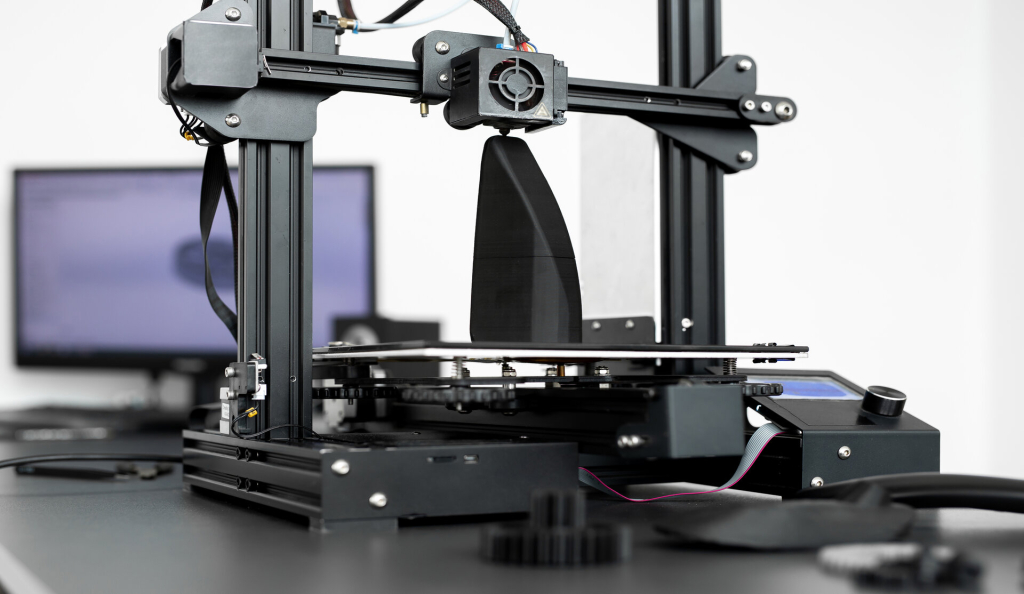

- Prototyping, 3D printing

- Production and testing of metal powders suitable for printing

- Examination of the properties of prototype products

TOOLS:

- Orlas Creator RA 3D laser metal printing equipment

- ATO Lab metal powder production equipment

- CTX Alpha 500 SINUMERIK 840D CNC turning center

- DMU 40 HEIDENHAIN iTNC530 CNC milling center