At our facility, we offer comprehensive support to industrial partners, addressing intricate production and operational challenges associated with welding processes. Our expertise extends to welding technology development, specialized training, and problem-solving in the industrial realm.

Competencies:

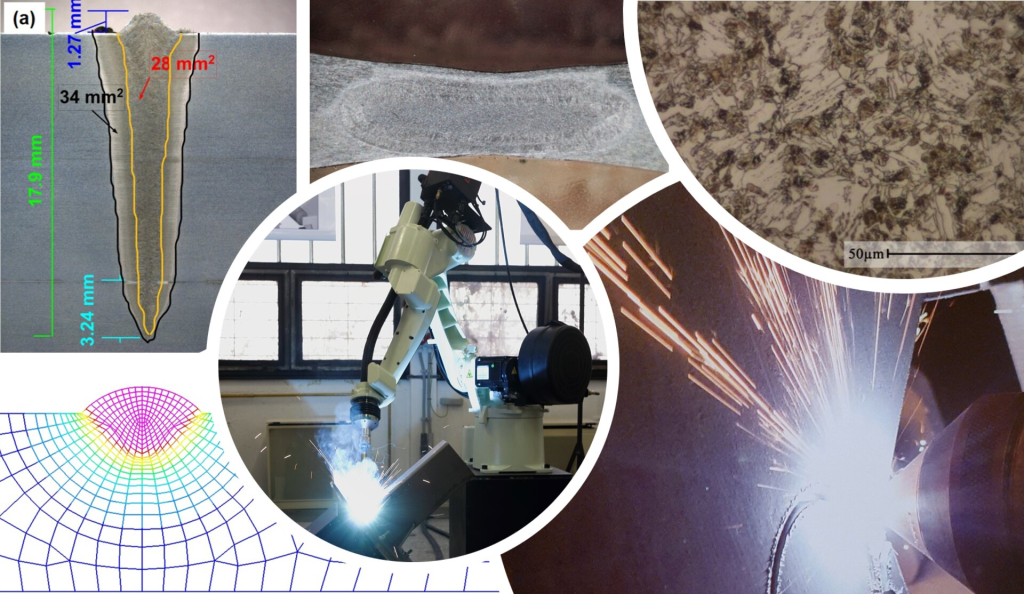

- Development of welding technology in fusion and pressure welding processes

- Assessment of welding technology through materials testing methods

- Analysis of construction for welding technology suitability, automation, and robotization potentials

- Numerical modeling and physical simulation of welding processes

Services:

- Theoretical and experimental-based welding technology elaboration, including processes, parameters, and filler materials, along with destructive testing of welded joints

- Investigation of welding problems in a virtual environment using SYSWELD

- Plasma cutting services

- Training programs including International and European Welding Engineer (EWE/IWE), European Welding Practitioner (EWP-RW), and Specialist (EWP-RS) for Resistance Welding, as well as company-specific short courses in fusion and resistance welding

Tools:

- Advanced welding equipment such as MIG/MAG and TIG units

- HKS measurement system for welding parameter registration and analysis

- TECNA 8007 resistance spot and projection welding equipment

- Welding robot laboratory featuring MIG/MAG processes

- Combined CNC plasma and flame cutting workstation

- SYSWELD FEM software for numerical modeling of welding processes

- GLEEBLE 3500 thermo-mechanical physical simulator

References:

- Collaboration with industry leaders like MOL Group, FGSZ Co., Joyson Safety Systems Ltd., Dometic Co., and Fortaco Co. for welding technology developments and failure analysis

- Delivery of resistance and fusion welding short training courses for organizations like Audi and Bosch

- Participation in projects like AUTOTECH and RMWF, focusing on automotive materials technologies and risk management in welding fabrication, respectively

- Contribution to the LoCoMaTech H2020 project, aimed at developing low-cost materials processing technologies for mass production of lightweight vehicles

Partner with us for cutting-edge solutions in welding technology, training, and industrial problem-solving. We are committed to driving innovation and excellence in the welding industry.