This competency involves researching the technologies used in the production of machine-industry products, solving technological problems, manufacturing custom-made components, and implementing technological experiments.

Competencies:

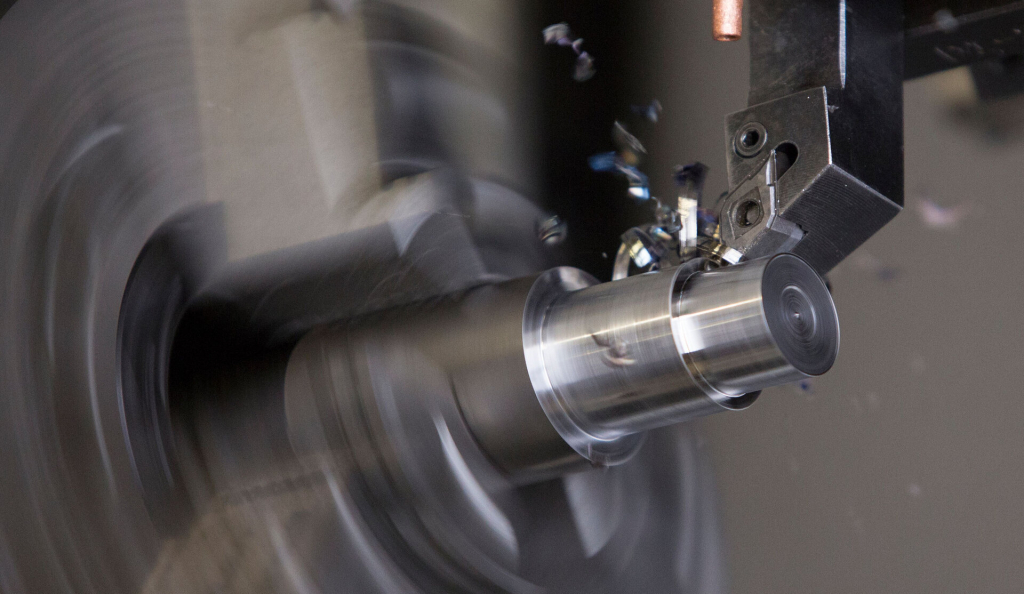

- Application of precision technologies for producing components meeting operational requirements, including hard machining and combined processes.

- Development of life-extending and environmentally friendly production technology for machine parts, including non-traditional machining methods.

- Fine machining and measurement of parts produced using additive technologies.

- Application of special cutting technologies for machining products with prescribed surface quality, including surface topography, hardness, and residual stresses.

Services:

- Surveying, planning, and consulting on manufacturing processes.

- Technological problem-solving, process development, and tooling.

- Machining of components in individual production runs.

- Implementation of technological experiments and research.

- Finite element simulation of cutting processes.

Devices:

- EMAG VSC 400 DDS hard machining center

- OPTIturn L440 CNC and OPTIturn S600 CNC turning lathes

- MCV-M8 CNC machining center

- FSM 4080 CNC surface grinder

- Mastercam 2020 CAM software

- ThirdWave AdvantEdge FEM software for cutting technology

- AltiSurf 520 type 3D measuring device for surface topography

References:

- ZF Hungária Ltd. (Eger): Implementation of high-speed surface milling with 80 mm diameter soldered insert PCD tool for machining gearbox housings.

- KIVA-TECH Ltd. (Miskolc): Manufacturing technology of various machine components, machining of parts.

- Bay Zoltán Applied Research Nonprofit Ltd. (Miskolc): Measurement of wear and surface characteristics of worn parts.