Our competence lies in providing robust support for the technological process planning of metal forming processes, leveraging both numerical and physical modeling. We specialize in conducting comprehensive investigations to solve complex problems in metal forming technologies, with a particular focus on addressing forming challenges in the automotive industry.

COMPETENCIES:

- Computer-aided Process and Die Design Planning with dedicated software

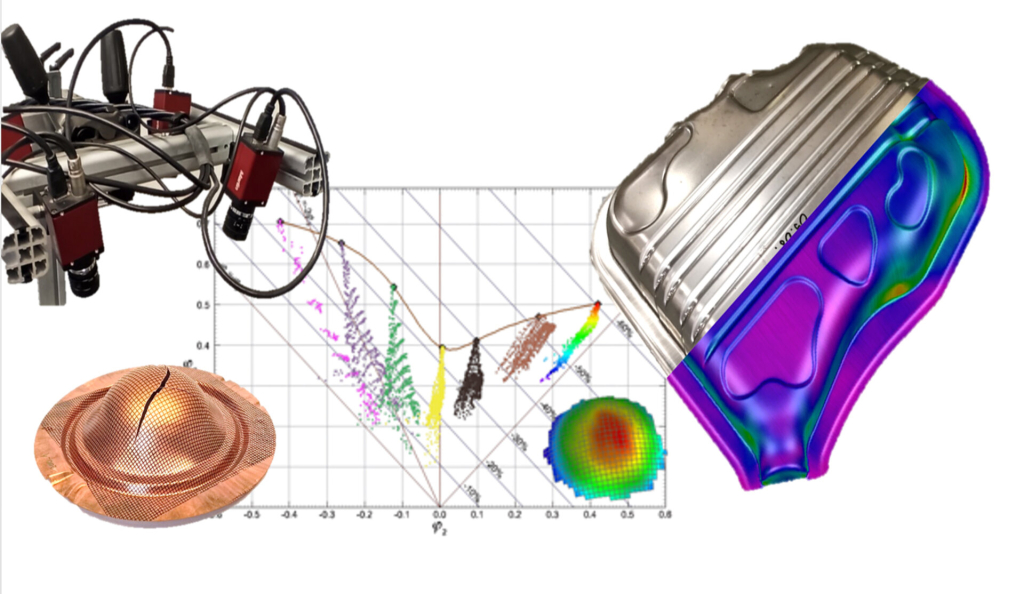

- Numerical modeling investigations of formability problems

- Determination of formability parameters based on physical measurements

SERVICES:

- Complex technology and die design in sheet metal forming (AutoForm R8)

- Investigation of formability problems in a virtual environment (with dedicated software)

- Determination of material parameters of formability with physical experiments (Nakazima test)

- Training in AutoForm and DEFORM applications

- Strain measurement with digital image correlation technique (Vialux-AutoGrid), 3D scanning

TOOLS:

- PYE-63 double-action hydraulic press

- DKS-40 and DKS-25 mechanical presses

- Universal sheet metal physical investigation system

- Vialux-AutoGrid optical strain measurement system

REFERENCES:

- LoCoMaTech H2020 project – Low-Cost Materials Processing Technologies for Mass Production of Lightweight Vehicles (www.locomatech.net/ProjectArea1/)

- Development of producing aluminum aerosol cans – Mátrametál Kft. (GINOP-2.2.1-15-2017-00035) (www.projekt.matrametal.hu)

- AutoForm training courses for automotive industry partners (Audi Hungária Zrt., Mercedes-Benz Manufacturing Hungary Kft., Hajdu Autotechnika Zrt.)

By combining advanced modeling techniques with practical experimentation, we contribute to enhancing metal forming technologies, ensuring efficiency, and addressing specific challenges faced by our clients in the automotive industry.