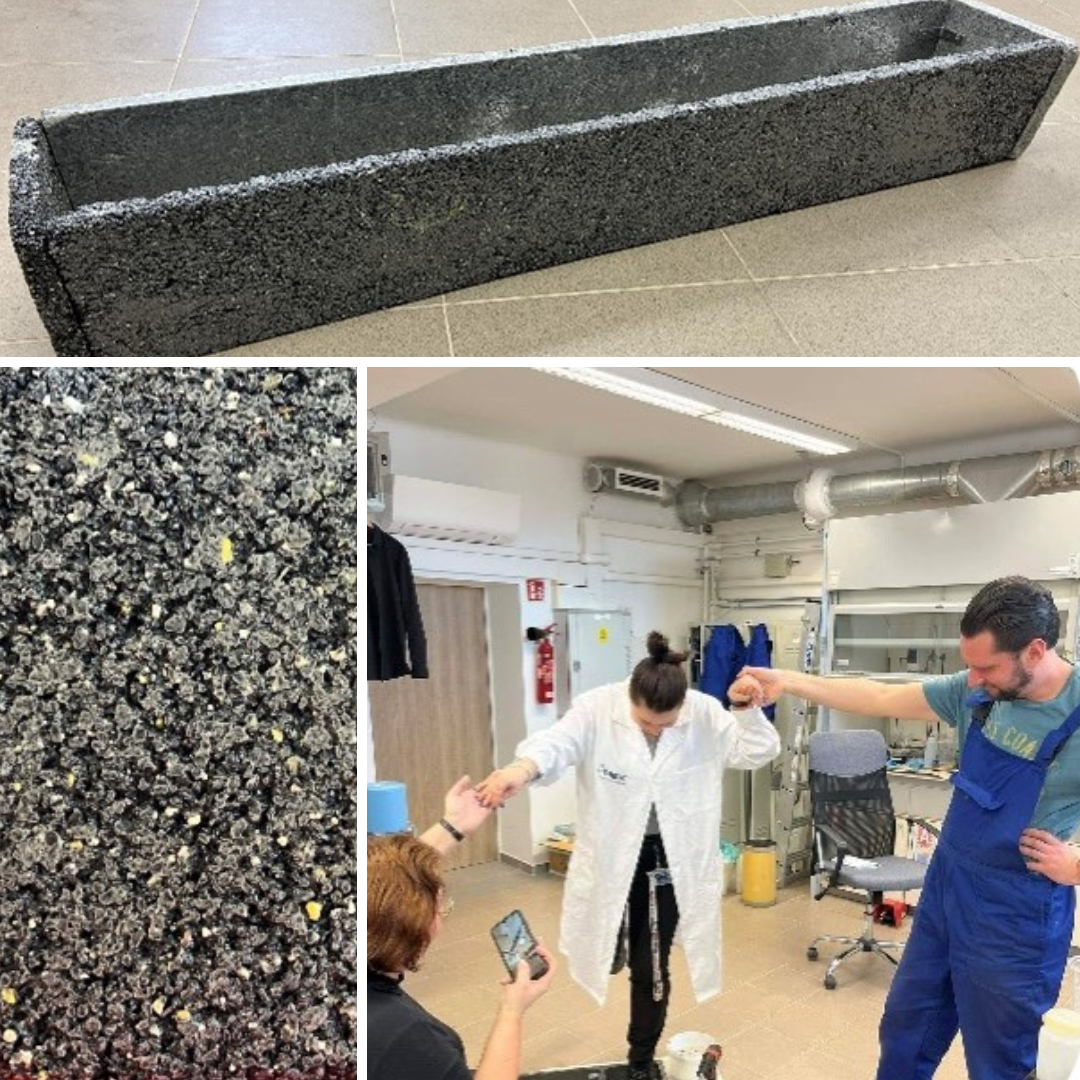

- The composite developed is made up of more than 50% plastic waste. Recipe that can be developed to meet specific needs.

- CO2 absorption.

- The inorganic phase in the composite absorbs CO2, which is incorporated into the structure of the material, strengthening it. The strength of the product is thus continuously increased.

- More than 50% plastic waste utilisation.

- Composite developed in-house and patent pending.

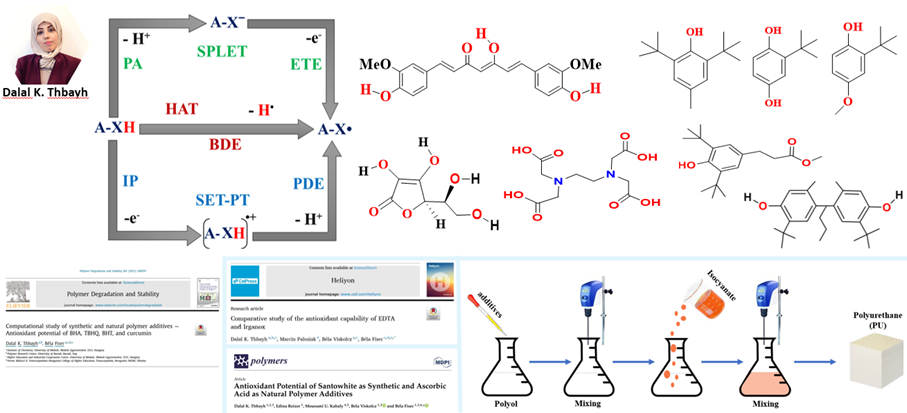

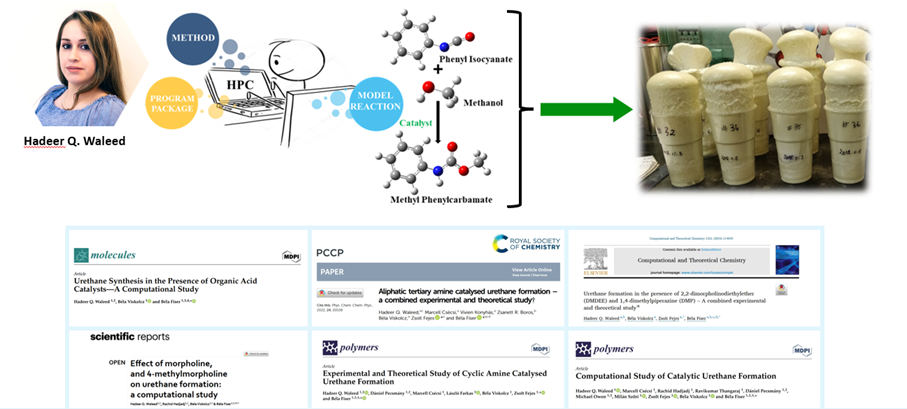

Computer Molecular Design Research Group and Polyurethane Research Laboratory

We are working in two connected research units, the Computational Molecular Design (CoMoDe) Research Group and the Polyurethane Research Laboratory (PUR Lab). Both belongs to the Institute of Chemistry and the Higher Education and Industrial Cooperation Centre at the University of Miskolc (Hungary).

• CoMoDe is an interdisciplinary research group working at the intersection of chemistry, physics, and biology with the aim to design environmentally friendly materials. Computational chemistry tools with the help of high-performance computing facilities are routinely applied by the members of CoMoDe in their research.

• The PUR Lab is collaborating with industrial partners (e.g. MOL, Wanhua-BorsodChem), but its activities goes beyond industrial needs and include the development of new polyurethanes (from computer models to synthesis), product optimization, development and refinement of synthetic processes, and all basic and targeted research in the field of PUR chemistry.

Here are a few example of our Research and Development activities:

BrickoPlast

AgroPlast

- The composite developed is made from more than 50% plastic waste and more than 10% construction waste.

- The product is coated with a leaching inhibitor and plant immune-boosting nutrient that dissolves into the soil and feeds the plant when watered, boosting its immune system.

- The product can bind any plastic waste and nurture new life.

- Our goal: To recycle waste into materials by creating an environmentally friendly composite material

Catalytic Urethane Synthesis